The 60TPD rice processing plant is a rice processing facility with a daily processing capacity of 60 tons. This rice processing unit utilizes advanced technology, featuring a high polished rice rate and a low broken rice rate. It integrates functions such as destoning, hulling, milling, grading, color sorting, and packaging.

What machines are used for rice milling?

Our 60TPD rice milling plant has different configurations depending on the customer’s needs, with different configurations using different numbers of machines. However, generally speaking, the equipment in the rice milling unit is roughly the same.

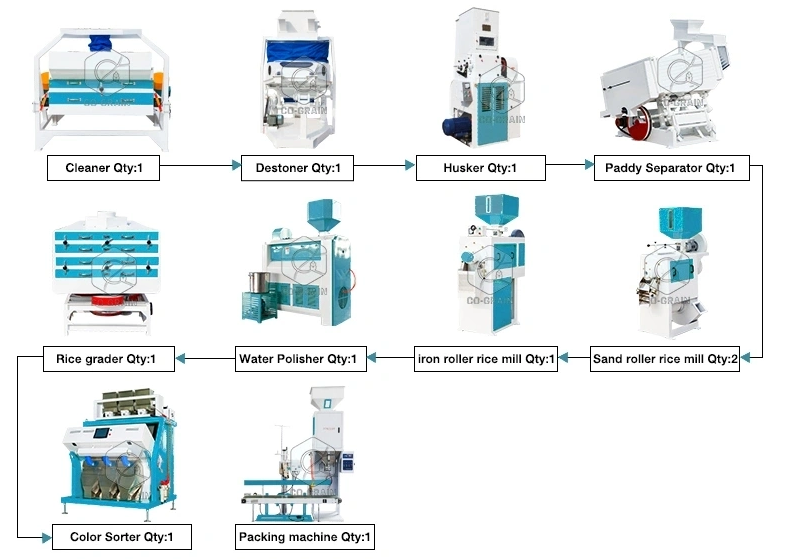

The list of machines used in rice milling is as follows:

Paddy Cleaner and Destoner: Removes impurities such as stones, soil, straw, and grass seeds from the grains. Through sieving and air separation, it ensures that the grains entering the next process are clean and free of impurities.

Paddy Huller: Uses mechanical force to separate the outer shell (paddy husk) from the inner kernel (brown rice), achieving the dehulling process.

Gravity Rice Separator: Effectively separates the mixture (brown rice and rice bran) obtained after rice hulling, improving the purity of the brown rice.

Rice Whitener: Utilizes the milling principle to gradually remove the bran layer from the surface of brown rice without damaging the endosperm, resulting in white rice. Depending on process requirements, multiple polishing processes may be necessary to ensure quality.

Polishing Machine: Polishes the milled rice to further remove residual trace amounts of bran, giving the rice a smooth and bright appearance and increasing its commercial value.

Rice Grading Machine: Screens and grades rice grains according to size, shape, and quality, ensuring uniform final product specifications to meet the size requirements of different markets.

Color Sorter: Identifies and removes discolored or diseased grains using photoelectric sensors, improving the overall quality and food safety of the finished rice.

Packaging Machine: Automatically weighs, fills, seals, and labels the product, completing standardized packaging for easy transportation, storage, and sales.

Modern Rice Processing Plant Technical Parameters

Brand: FOTMA

Machine Name: 60TPD Rice Mill

Model: MCTP60

Capacity: 2300-2700 kg/hour

Applicable Grain: Rice

Power: 143 kW

Dimensions: 14500*2950*4600 mm

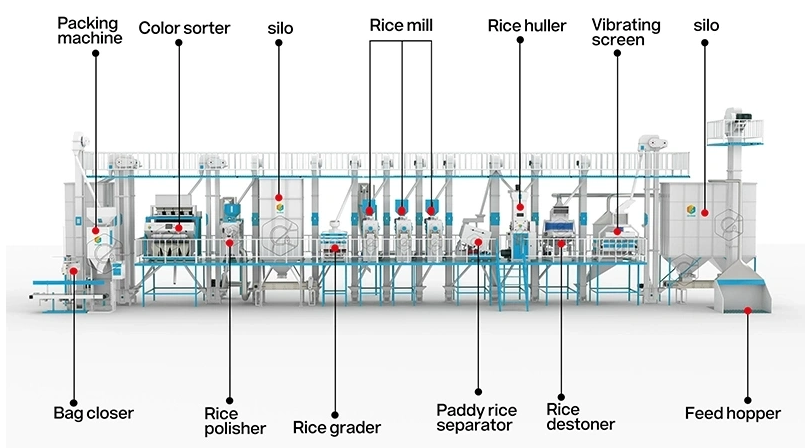

Rice Processing Plant Flowchart

This flow chart explains the working principle of a rice mill. It greatly helps you understand the workflow and become familiar with the machinery.

Advantages of the Modular Rice Mill

The individual machines of the 60TPD rice mill are arranged in a row, neat and aesthetically pleasing.

The milling section of this equipment uses advanced milling technology, resulting in low rice temperature, less bran, and a low breakage rate.

Main operations are concentrated on one side, making operation convenient.

Energy-saving, environmentally friendly, simple to operate, easy to maintain, and durable.

Large capacity, high speed, and stable performance.

Different configurations are available. We can recommend a suitable 60TPD rice mill to meet your requirements.

Optional Equipment for Complete Rice Milling Units

A 60tpd rice milling plant machine offers various combinations to achieve your desired goals. In addition to this 60tpd rice mill, we also have other machines that can be added.

Rice Polishing Machine

This machine is used in the rice milling production line to make the rice whiter and smoother.

Color Sorter

The color sorter can distinguish between high-quality white rice and moldy black rice. This is very helpful for high-quality white rice.

Packaging Machine

Since the ultimate goal is to sell the white rice, packaging is a necessary step. The packaging machine for this rice mill ranges in weight from 5 kg to 50 kg. Therefore, it is very practical.

From the above, we can see that a complete rice milling production line for sale offers different combinations to meet your business needs.

Features of a 60-ton-per-day rice milling plant:

1. This rice milling plant can process both long-grain and short-grain rice (round rice), suitable for producing white rice and parboiled rice, with high rice yield and low broken rice rate;

2. This production line combines a bucket elevator, vibrating cleaner, destoner, huller, paddy separator, and dust removal device, making it practical and environmentally friendly;

3. This production line can produce high-precision rice, suitable for commercial rice production;

4. It has excellent impurity and stone removal performance;

5. All components are made of high-quality materials, durable, and reliable;

6. The entire set of equipment has a compact and reasonable layout, is easy to operate and maintain, and saves workshop space;

7. A rice color sorter and packaging machine are optional.

Services Offered by Modular Rice Milling Machines

For rice milling units, we offer the following services:

Equipment Sales and Customization: We provide complete rice processing plant equipment with different production capacities, such as 15-ton/day rice milling units, 25-ton/day units, etc., and can customize rice milling machines with special specifications and configurations according to your needs.

Technical Consultation and Design: Based on your specific needs, raw material characteristics, and site conditions, we provide professional rice milling production line design and technical consultation services.

After-Sales Support and Maintenance: Free repair or replacement of faulty parts during the equipment warranty period; timely technical support and paid maintenance services after the warranty period.

Spare Parts Supply: We provide a long-term supply of various original spare parts required by rice processing plants, ensuring the quality and compatibility of replacement parts during equipment use.

Start your rice milling business today!

Please contact us as soon as possible. We will design a suitable machine match according to your specific needs to meet different rice milling requirements. We always put the interests and quality of our customers first, providing high-quality products and comprehensive on-site service. After-sales service is carried out according to all commitments.

Our specific commitments are as follows:

We will ensure timely delivery of complete sets of equipment and accessories;

We will ensure successful installation and commissioning;

We will provide users with high-quality materials and preferential prices;

We will prioritize providing customers with new products and processes;

We will provide free training to operating technicians to ensure trainees can operate independently;

We will assign an experienced installation project manager and organize a technical installation team to conduct on-site installation and commissioning;

After on-site assembly and installation, we will be responsible for the individual machine commissioning, online commissioning, and trial operation to ensure the equipment operates normally at full load. We will provide all necessary documents and records as required by the contract. According to customer requirements.

Post time: Nov-09-2025