Thank you for purchasing the FOTMA-manufactured 6N-4 mini rice milling machine. Before using it, please carefully read the instruction manual.

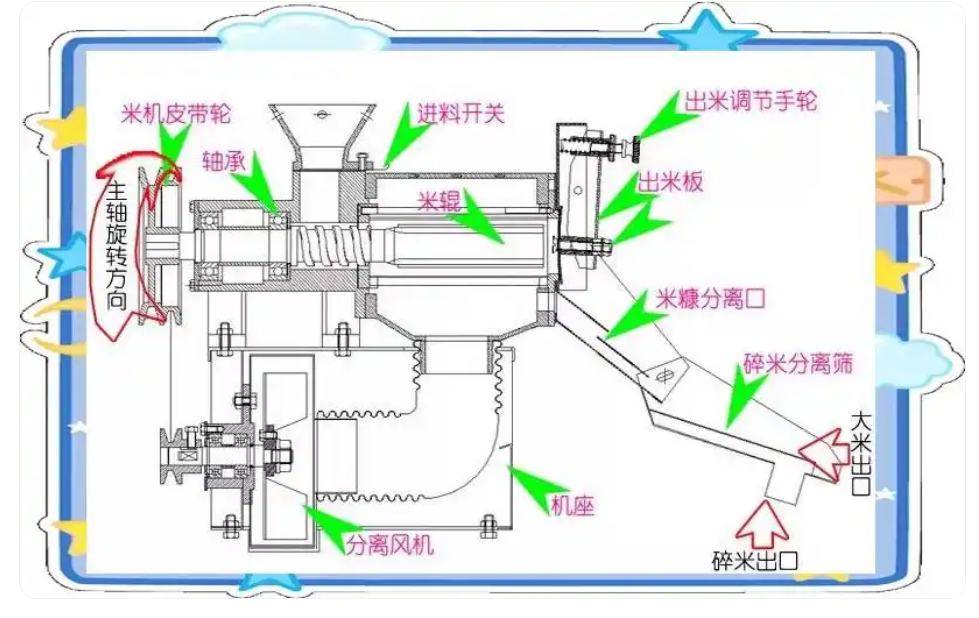

Structure and Principle of the 6N-4 Mini Rice Milling Machine

The 6N-4 rice milling machine includes a base, drive shaft, rice rollers, fine sieve, blower, and inlet and outlet hoppers. These components work together to ensure efficient operation and high-quality output.

Working Principle and Supporting Information

The 6N-4 rice milling machine is equipped with a 2.2kW power supply and uses a 220V two-phase voltage. During the rice milling process, paddy rice enters the milling chamber through the feed hopper and is conveyed by the high-speed rotating rice rollers. The paddy rice is dehulled through friction between the rice rollers and the rice sieve. Simultaneously, the combined friction and kneading of the hexagonal rice sieve and the rice rollers further dehulls and whitens the paddy rice, separating the bran. After separation, the rice bran flows out through the sieve holes under the force of the blower, while the rice flows out from the outlet after passing through the rice discharge regulating device. Additionally, the rice bran mixture flows out through the rice discharge plate, and then passes through the rice bran separation port and broken rice separation sieve, thus achieving automatic separation of rice, broken rice, and bran powder.

Installation Steps

First, install the separating blower in place, ensuring the separating blower and V-belt are correctly installed, and ensuring the bran powder outlet of the rice milling machine is precisely aligned with the blower inlet. Then, securely install the rice milling machine.

Installation Precautions

During installation, pay attention to adjusting the tension of the V-belt. It should be able to be easily pushed with your fingers with a 15-20mm allowance. Before starting the machine, be sure to check the rotation direction of the rice milling machine’s main shaft to ensure it matches the schematic diagram. After installation, check the fasteners and adjusting mechanism, ensuring the adjusting mechanism operates smoothly and listening for any abnormal noises.

Operating Points and Usage Tips

When operating the 6N-4 rice milling machine, the following key steps and points must be followed to ensure normal machine operation and rice milling effect. Pressure reduction is required during the initial debugging of a new machine. After starting the motor power, carefully listen for any abnormal noises from the rice milling machine to ensure its normal operation.

Usage Tips

Gradually open the feed switch while observing the rice output. Fine-tune the process by appropriately rotating the rice output adjustment handwheel until the ideal rice milling effect is achieved, then lock it. The broken rice rate can be optimized by adjusting the angle of the rice output plate and rice sieve to avoid jamming and the mixing of whole rice with bran powder, ensuring the continuity and safety of the rice milling process.

Patent Technology Introduction

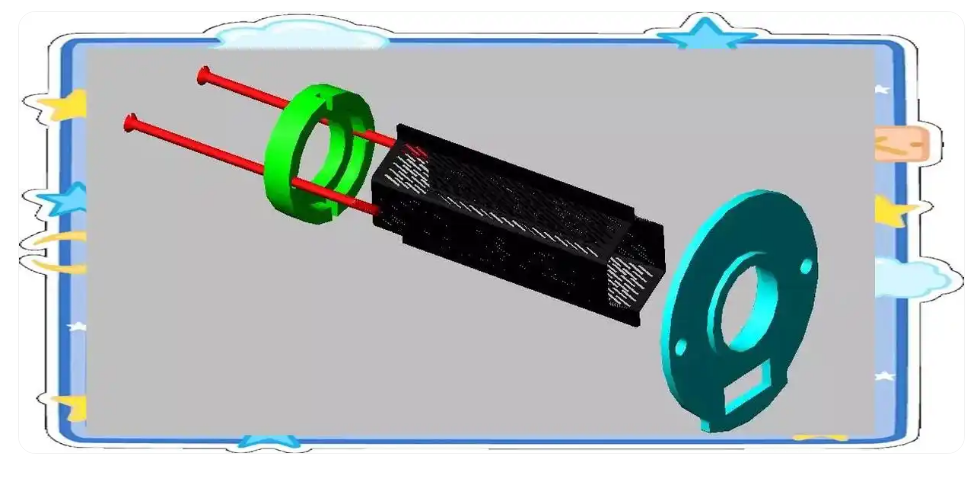

Hexagonal Rice Sieve Holder

Our company’s independently developed patented technology, the hexagonal rice sieve holder, aims to solve the problem of maintaining the relative position stability and disassembly accuracy of the hexagonal rice sieve in the absence of rice cutters on the 6N-4 rice milling machine. The patented holder ensures the relative position of the sieve is stable, thereby improving work efficiency and ensuring the rice milling machine operates efficiently and stably.

Post time: Dec-03-2025