Currently, during the crucial autumn grain harvest season, rice drying work in Qingpu District is progressing smoothly. Grain drying centers are bustling with activity, with staff working in shifts 24 hours a day to expedite drying and prevent mold growth, thus minimizing the difficulties faced by surrounding grain farmers in drying and storing their grain.

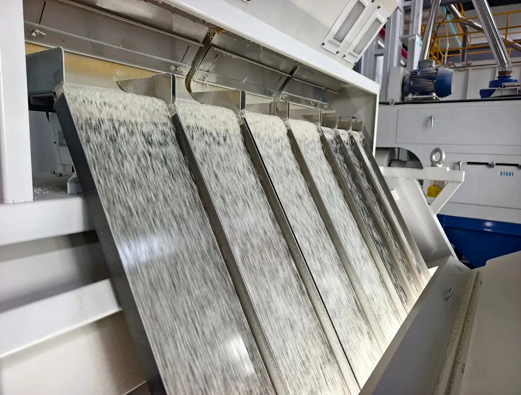

At Shahai Qingxi Green Rice Storage and Transportation Co., Ltd., five 10-meter-high, 30-ton “FOTMA” advanced drying machines are operating at full capacity, their roar echoing as they rapidly dry the freshly harvested rice. Alongside these are hot air furnaces and grain cleaning machines, along with dust removal and conveying equipment, forming a modern grain drying production line. After a series of automated processes by the drying system, the rice becomes dry, bright-colored, and meets standards. The dried rice is then stored in grain silos for later use. The entire process is highly efficient and smooth, showcasing the superiority of mechanized operations. The entire process is highly efficient, smooth, and seamless, showcasing the superiority of mechanized operations. The transformation from “wet grain” to “standard-compliant grain” can be completed in less than 24 hours.

“The wet rice delivered by customers has a moisture content of approximately 28%-30%. We will reduce the moisture content to 14.5%-15% through drying operations, with a drying cycle taking about 24 hours,” explained Wu Jiacong, head of Shanghai Qingxi Green Rice Storage and Transportation Co., Ltd. After drying, the rice undergoes ventilation and cooling, followed by milling operations based on farmers’ needs. “Currently, it’s peak farming season, with a daily drying capacity of 150 tons and a milling capacity of 60 to 70 tons.”

This efficient service has greatly benefited surrounding grain-growing enterprises. Shanghai Zizai Qingxi Agricultural Development Co., Ltd., which cultivates 2,200 mu of rice in Liantang Town, is currently harvesting its main variety, “Qingxiangruan 526.”

“Currently, one-third of the rice harvest is complete. Thanks to the FOTMA grain drying center, we can arrange harvesting, drying, and rice processing according to plan, saving us a lot of trouble,” said Feng Wenxiao, head of the company’s production department. He explained that the proximity of the fields to the processing and storage center reduces transportation time and prevents the rice from getting damp during transport. More importantly, the center’s green processing standards align with the company’s green food positioning. “Our rice isn’t all milled on the same day; the center also has cold storage to help with storage, solving our warehousing problems and ensuring quality and safety.”

The autumn grain harvest season is most vulnerable to rainy weather. If the rice isn’t dried in time, it’s prone to mold. To ensure that every grain is safely stored, the drying center has increased equipment maintenance efforts in advance, arranging for staff to work in 24-hour shifts to ensure uninterrupted operation.

“Even on rainy days, we can guarantee that the wet grain is dried in time, ensuring that the farmers’ hard work isn’t wasted,” said Wu Jiacong. Beyond drying, this integrated processing center boasts a comprehensive “full-chain service” capability: it not only provides grain drying but also houses two 1,500-ton steel-plated grain silos, a 2,000-square-meter near-low-temperature grain storage facility, and a low-temperature rice storage facility, ensuring precise control over rice taste and quality. Simultaneously, it possesses the capacity for green rice (rice flour) processing, packaging, and transportation, with a daily production line capable of producing 1 ton of rice flour and an annual capacity of 28,000 tons of high-quality refined rice, which can drive large-scale, standardized, and industrialized grain production in the surrounding area.

“From paddy drying to storage, processing, and finally the production of safe and nutritious rice and rice flour, we leverage FOTMA’s full-chain equipment and management to alleviate farmers’ worries about ‘what to do after a bumper harvest’,” said Wu Jiacong. He added that they will continue to deepen their cooperation with FOTMA to optimize services, achieving “green premium prices” through green synergy across the entire industry chain, allowing more farmers to enjoy the benefits of modern agricultural development.

Post time: Dec-10-2025