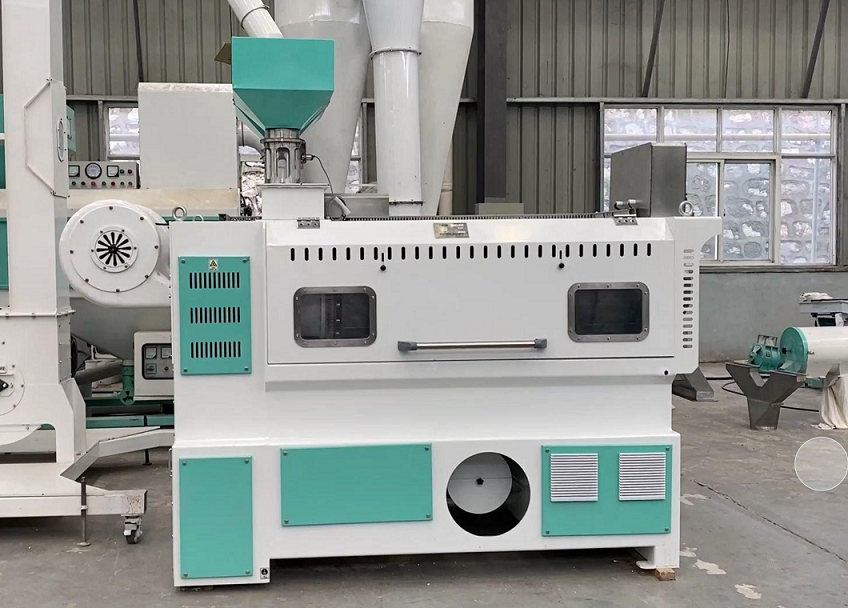

Intelligent Flexible Rice Polishing Machine is our latest patented invention product. The application of this machine in rice processing technology:

Iron roller whitening → cooling rice → intelligent flexible rice polishing machine → iron roller polishing machine. Because the rice after whitening contains some broken powder and fine powder, this product can replace one iron roller polishing machine, and can also completely separate the powder and rice and polish them, reducing the traditional iron roller polishing machine. It effectively reduces power consumption, reduces breakage, and improves the yield of finished products. The scientific research results of this product will be another innovation in rice processing technology. It is of great significance to stop excessive processing and ensure food security.

Equipment features:

Because rice contains broken powder and fine powder, this product can be used to completely separate and polish the powder and rice;

Low energy consumption, high yield

Effectively reduce power consumption, reduce crushing, and improve the yield of finished products;

Intelligent adjustment device

The electrical control adopts PLC programming control, equipped with LCD liquid crystal visual screen human-machine interaction interface, 232 communication data link port;

Accurately control the feed amount

This product will be another innovation in rice processing technology, which is of great significance to control over-processing and ensure food security

2. The maximum output of this product is 24 tons per hour, and the total design power is 35.9KW. Compared with the traditional rice polishing machine with a designed output of 24 tons per hour and a total design power of 90x2KW, the power consumption per ton of material is 5 times that of the intelligent flexible rice polishing machine.

3.1700x400mm polishing chamber, high-pressure internal air jet device, strong ventilation and fast rice cooling speed

Structural advantages:

1. The main shaft connection base block and thread rolling in the kneading chamber are made of new high-wear-resistant food-grade materials with a service life of ≥7000 hours;

2. The main shaft and the kneading screen frame are equipped with precision rotary shaft teeth and rotate at the same time at a differential speed. It can withstand large axial and radial loads and overturning moments at the same time and is durable;

3. It is equipped with a sharp lip-shaped dustproof gasket, which is wear-resistant and dust-proof;

4. The screen plate material is treated with ion double carburizing technology, which is durable, and a high-pressure internal air jet device is set in the polishing room;

5. The observation door structure supported by hydraulic gas springs, the rubbing room is equipped with an LED lighting visual system, and the inlet and outlet contact material surfaces are made of SUS304 food-grade stainless steel;

6. The electrical control adopts PLC programming control, equipped with a 15-inch LCD liquid crystal visual screen human-computer interaction interface, and a 232 communication data link port is reserved;

7. The main shaft drive and the outer screen frame drive are respectively equipped with variable frequency speed regulators, using Swedish NSK/SKF bearings, the main motor uses Siemens Bede motor, and the driving wheel and driven wheel adopt an internal tension sleeve structure, which is easy to disassemble and maintain;

8. The feeding system adopts servo motor sensor interlocking control, which can accurately control the feeding amount. The feeding and discharging ends are clearly visualized.

Post time: Jul-01-2025