In the grain and oil industry, especially in rice processing, an efficient production process is key to a company’s success. For companies that need to process large quantities of rice daily, a stable and efficient rice processing production line is crucial. This article will provide a detailed introduction to the process flow and working principle of a 200-ton-per-day rice processing production line, and combine it with practical application cases to help you better understand and manage the production line.

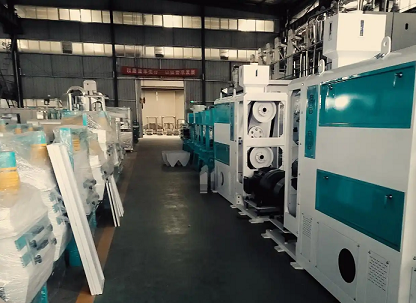

I. Production Line Overview

A 200-ton-per-day rice processing production line typically consists of multiple processes, including cleaning, hulling, milling, polishing, color sorting, and grading. Each process has its specific function, working together to complete the transformation from paddy rice to finished rice. Such a production line not only improves production efficiency but also ensures the consistency and stability of product quality.

II. Introduction to Main Processes

1. Cleaning Process

The cleaning process is the first and crucial step in the entire production process. It mainly removes impurities from the paddy rice, such as stones, metal, and weeds, through methods such as air separation, magnetic separation, and sieving. This not only improves the efficiency of subsequent processes but also prevents impurities from damaging machinery. We recommend using high-efficiency cleaning equipment manufactured by FOTMA MILL, which boasts superior cleaning capabilities and durability.

2. Hulling Process

The main purpose of the hulling process is to remove the outer husk of the paddy rice. This process is typically completed using a hulling machine, achieved through the friction between a high-speed rotating grinding wheel and the paddy rice. Choosing the right hulling machine is crucial for increasing rice yield and reducing broken rice. FOTMA MILL’s hulling machines are widely praised for their high efficiency and low energy consumption.

3. Milling Process

The goal of the milling process is to remove the brown rice layer from the paddy rice, resulting in the white rice we commonly see. This process is generally completed using a rice milling machine. The choice of rice milling machine is equally important, as it directly affects the taste and nutritional value of the final product. FOTMA’s rice milling machines offer excellent milling performance to meet the needs of different customers.

4. Polishing Process

The polishing process is to make the surface of the rice smoother, improving the appearance quality of the product. Polishing machines achieve a polishing effect by applying appropriate pressure and friction to the rice. High-quality polishing machines can significantly improve the gloss and taste of rice. FOTMA MILL’s polishing machines enjoy a high reputation in the industry.

5. Color Sorting Process

The color sorting process uses optical principles to identify and remove substandard rice grains, such as discolored rice and insect-damaged rice. The application of color sorters greatly improves the quality of finished rice. FOTMA’s color sorters are renowned for their high precision and ease of operation.

6. Grading Process

The final step is the grading process, which sorts the rice according to its size and shape. This process helps improve the market competitiveness of the finished rice. Our grading equipment has excellent grading effects and can meet the needs of different customers.

III. Maintenance and Care Recommendations

To ensure the long-term stable operation of the production line, regular maintenance and care are essential. It is recommended to establish a detailed maintenance plan, including daily inspections, regular replacement of worn parts, and timely system upgrades. In addition, operators should receive professional training and be familiar with the equipment’s operating procedures to reduce malfunctions caused by misoperation.

In summary, a 200-ton-per-day rice processing production line is a complex but highly efficient system. Through reasonable process design and scientific equipment selection, production efficiency and product quality can be effectively improved. We hope this article provides useful reference and guidance for your production line management. If you are interested in any of the equipment mentioned above or have any questions, please feel free to contact us!

The above content aims to provide readers with a comprehensive understanding of the process flow and working principles of a 200-ton-per-day rice processing production line, and emphasizes the importance of equipment maintenance. We hope this information will help you better manage and optimize your production line, thereby promoting the healthy development of your business.

Post time: Feb-18-2026