Excellent quality Best Oil Extraction Machine - Solvent Leaching Oil Plant: Loop Type Extractor – Fotma

Excellent quality Best Oil Extraction Machine - Solvent Leaching Oil Plant: Loop Type Extractor – Fotma Detail:

Product Description

Solvent leaching is a process to extract oil from oil bearing materials by means of solvent, and the typical solvent is hexane. The vegetable oil extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seeds containing less than 20% oil, like soybeans, after flaking. Or it extracts oil from pre-pressed or fully pressed cake of seeds containing more than 20% oil, like sunflowers, peanuts, cotton seed and a variety of other materials.

During the technology of leaching, the leaching process is the most important section of the whole technology, no matter it is for directly leaching from flacks, leaching of pre-pressed cake or leaching of puffed material, which working principle are the same, but the pre-treatment of the material is different, so there are some of the difference on processing condition and selections of equipments from different material.

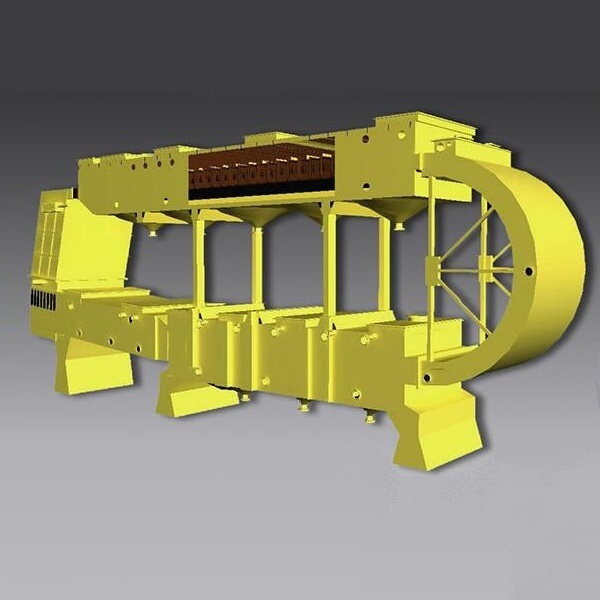

The loop type extractor adapt large oil plant for extracting, it adopts a chain driving system, it is one potential extraction method available in the solvent extraction plant. The new loop-structure ensures less power consumption, less maintenance, and reduces noise. The rotation speed of loop-type extractor can be adjusted automatically according to incoming oilseed’s quantity to ensure that the bin level is stable. This will help to form micro negative-pressure in the extractor to prevent the escape of solvent gas. What’s more, its biggest characteristic is the oilseeds from the bending section to turn into the substratum, makes extracting oil more uniform thoroughly, shallow layer, wet meal with less solvent content, residual oil amount to less than 1%.

Features of loop type extractor

1. Loop type extractor adopts chain transmission, new type of unique circular structure, equipped with frequency controlled motor, low power consumption, low rotation speed, stable running without noise.

2. The feeding system can automatically adjust the running speed of main motor according to different material and amount to maintain a certain material level of the storage tank. It is conducive to the formation of micro negative pressure inside the extractor so as to prevent leakage of solvent.

3. The advanced miscella oil circulation is conducive to reduce the input amount of fresh solvent, decrease the residual oil content in meal, and imcrease the concentration of miscella, and lower the evaporating amount to achieve the purpose of energy saving.

4. The material layer of extractor is designed as lower and uses percolation leaching. Materials would be rotated in the bending section to reduce the blind side of leaching. However, in cases of significant dregs in the miscella is high, the dregs are effectively disposed of before entering the evaporation system.

5. It takes full negative pressure evaporating in evaporation system, with high heating utilization efficiency and helps to improve the quality of leached oil.

6. It takes completely negative pressure technology of condensing system, with high heat transfer efficiency.

7. Horizontal stainless steel multitubular condenser is used with high solvent recovery rate. Less occupied area for condenser help to save the investment of the project.

8. The procedure in the workshop can be computerized controlled, including the temperature, pressure, liquid level and evaporating flow, etc.. The adjusting display records of the production parameter, status record of breakdown and outage, maintenance data sheet of equipment are provided through the embedded database. The control cabinet take controlling software, large screen monitor, kinds of data, report and corresponding printing, be synchronous displayed by remote launching control system, to process fault diagnosis and analyze at remote and long-distance, so as to proved timely and effectively technology support.

9. Take paroline for solvent recovery from vent gas, the vent gas contains less solvent.

10. The layout of workshop is reasonable, elegant and generous.

|

Model |

Capacity(t/d) |

Power(kw) |

Main application |

Mark |

|

YHJ100 |

80~120 |

4 |

Use for extracting oil of various of oilseeds |

Especially suitable for the good permeability oilseedssuch as soybean

|

|

YHJ150 |

140~160 |

5.5 |

||

|

YHJ200 |

180~220 |

7.5 |

||

|

YHJ300 |

280~320 |

11 |

||

|

YHJ400 |

380~420 |

15 |

||

|

YHJ500 |

480~520 |

15 |

Product detail pictures:

Related Product Guide:

With dependable high quality approach, great reputation and excellent customer support, the series of products and solutions produced by our firm are exported to lots of countries and regions for Excellent quality Best Oil Extraction Machine - Solvent Leaching Oil Plant: Loop Type Extractor – Fotma , The product will supply to all over the world, such as: Sri Lanka, Sri Lanka, Malaysia, We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.