FMLN15/8.5 Combined Rice Mill Machine with Diesel Engine

Product Description

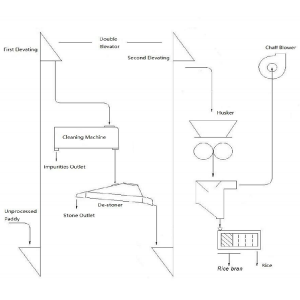

FMLN-15/8.5 combined rice mill machine with diesel engine is composed with TQS380 cleaner and de-stoner, 6 inch rubber roller husker, model 8.5 iron roller rice polisher, and double elevator. rice machine small features great cleaning, de-stoning, and rice whitening performance, compacted structure, easy operation, convenient maintenance and high productivity, reducing the leftovers at the maximum level. It is a kind of rice processing machine especially suitable for those areas where electricity power is shorted.

Key Component

1.Feeding hopper

Steel frame structure, which is more stable and durable. It can hold a bag of rice at a time, which is low in height and easy to feeding.

2.Double elevator

Double elevator is compact in structure and low in energy consumption. One side of lifting transports the uncleaned rice from paddy inlet, it flows into the other side of the lifting and transports to husker machine for shelling after being cleaned and treated by the stone removing machine. The two common powers for lifting do not interfere with each other.

3.Flat rotary cleaning sieve

Two-layer flat rotary cleaning sieve, the first layer sieve can effectively remove the large and medium impurities such as straw and rice leaves in the rice, the rice enters the second layer sieve, screens out the fine grass seeds, dust, etc. The impurities in paddy will be cleaned with high efficiency.

4.De-stoner

The de-stoner adopts a large air volume blow design, which has a large air volume and

efficiently removes stones that cannot be screened by the cleaning sieve.

5.Rubber roller husker

It adopts the universal 6- inch rubber roller husker to shell, and the shelling rate can reach more than 85%, when the brown rice is less damaged. The husker has simple structure, small consumption and can easy to ma intenance.

6.Husk separator

This separator has strong wind power and high efficiency to remove the chaff in the brown rice The damper is easy to adjust, and the fan shell and the fan blades are made of cast iron, which is durable.

7.Iron roller rice mill

Strong inhale-air iron roller rice mill, low rice temperature, cleaner rice, special rice roller and sieve structure, low broken rice rate, high gloss of rice.

8.Single cylinder diesel engine

This rice machine can be powered by a single-cylinder diesel engine for power shortage areas and mobile rice processing needs; and it is equipped with an electric starter for easy and convenient operation.

Features

1.Single cylinder diesel engine, suitable for power shortage areas;

2.Complete set rice processing procedure, high rice quality;

3.Unibody base designed for convenient transportation and installation, stable operation, low space occupation;

4.Strong inhale steel roller rice milling, low rice temperature, less bran, improve rice quality;

5.Improved belt transmission system, more convenient to maintain;

6.Independent safe diesel electric starter, easy and convenient to operate;

7.Low investment, high yield.

Technical Data

| Model | FMLN15/8.5 | |

| Rated output(kg/h) | 400-500 | |

|

Model/Power |

Electromotor(KW) | YE2-180M-4/18.5 |

| Diesel engine(HP) | ZS1130/30 | |

| Rice milling rate | >65% | |

| Small broken rice rate | <4% | |

| Rubber roller dimension( inch) | 6 | |

| Steel roller dimension | Φ85 | |

| Overall weight(kg) | 730 | |

| Dimension(L×W×H)(mm) | 2650×1250×2350 | |

|

Packing dimension(mm) |

1850×1080×2440(Rice mill) | |

| 910×440×760(Diesel engine) | ||