Manufacturing Companies for Olive Oil Extractor - Edible Oil Extraction Plant: Drag Chain Extractor – Fotma

Manufacturing Companies for Olive Oil Extractor - Edible Oil Extraction Plant: Drag Chain Extractor – Fotma Detail:

Product Description

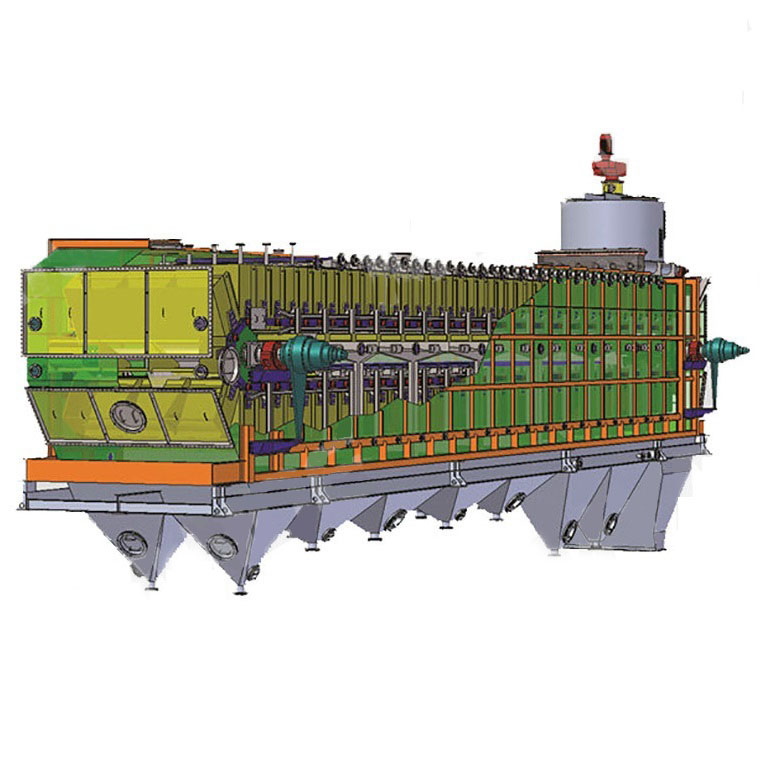

Drag chain extractor is also known as drag chain scraper type extractor. It is quite similar with the belt type extractor in structure and form, thus it can also be seen as the derivative of the loop type extractor. It adopts the box structure that removes the bending section and unifies the separated loop type structure. The leaching principle is similar as the ring extractor. Though the bending section is removed, materials could be stirred completely by the turnover device when falling into the lower layer from the upper layer, so as to guarantee the good permeability. In practice, the residual oil can reach 0.6% ~ 0.8%. Due to the absence of the bending section, the overall height of drag chain extractor is quite lower than the loop type extractor. It is more suitable for materials with high oil content and high powder.

Drag chain extractor that produced by FOTMA combined with years of production experience and a variety of technical parameters, on the basis of absorbing foreign advanced technology development of a new type of grease continuous leaching equipment. The drag chain extractor is adapted to extraction of various raw materials, such as soybean, rice bran, cottonseed, rapeseed, sesame seed, tea seed, tung seed, etc. oil squeeze plants cake leaching, protein of alcohol extraction. The drag chain extractor is easy to operate, safe and reliable, has low noise and significant effect of extraction, low power consumption, low solvent consumption and low residual oil content in meal. Although it occupies more space than loop type extractor, there is less stress on the chain and prolong its service life. It is easy to transport and install, feeding and discharging equably and there is no bridging happens.

The oil extraction process of our company includes rotocel extraction, loop type extraction and drag chain extraction with reliable design, installation and operation, full energy saving measures and low consumption index of water, electricity, steam and solvents. The technology we adopts has reached the international advanced level and in the leading position of professional equipment in our country.

The basic principle of operation

When oil plants are fed into the oil extractor after being rolled into flakes or expanded and forms a certain height of material layer, then the solvent (6# light gasoline) would be sprayed massively by the spray pipe to a certain level on the surface of material layer. Meanwhile, the scraper chain driven by the driving device will push materials forward slowly and evenly. Through repeated spraying and soaking by solvent (mixed oil), oil in the oil plants could be slowly dissolved and precipitated in the solvent (commonly known as the mixed oil). Mixed oil would flow into the oil collection bucket through the filtering of gate plate, and then the mix ed oil of high concentration would be sent into the temporary storage tank by the oil pump and transported to the evaporating and stripping section. The mixed oil of lower concentration is used in the circulating spray. With nearly 1 hour of extraction, the oil in oil plants is completely extracted. Cakes produced after extraction would be pushed into the meal mouth of extractor by the chain scraper and sent into desolventizer toaster for solvent recovery by the wet meal scraper. Scope of application: drag chain extractor can be used to extracting various raw materials, such as soybean germ, rice bran, etc. It can also be used for pre pressing cake leaching of oil plants like cottonseed, rapeseed, sesame seeds, tea seeds and tung seed.

Features

1. The entire drag chain type solvent extractor has a simple structure, convenient operation and high efficiency.

2. Adopting new techniques and advanced uniform box structure, that unifies the separated upper and lower layer of loop type structure, with good permeability, ensure uniform and better spraying, the residual oil rate can reach 0.6-0.8%.

3. Designed with a high bed, the solvent extractor has a good processing capacity. During the extracting process, the solvent and miscella get enough time to contact and mix with raw materials, allowing for quick saturation, high extraction and low oil waste.

4. Material can be segmented to many independent small units in the material bed, which can effectively prevent the mixed oil’s top current and interlayer convection, and highly improve the concentration gradient between every spray sections.

5. The self-cleaning V-shape plate guarantees not only smooth and non-clogging operation, but also high penetration speed.

6. With the combination of the scraper and a moving belt, the solvent extraction equipment delivers materials by taking advantage of the friction between crops, with a simpler structure and decreased load to the entire machine.

7. By applying a variable-frequency speed controller, the extraction time and processing quantity can thus be regulated conveniently and easily. Moreover, it creates a sealing environment in the feed hopper, which prevents the mixed steam from flowing backward to the preparation part.

8. The latest material feeding device can adjust the height of the material bed.

9. The soaking zone is formed in each feed lattice, which can achieve better immersion effect.

10. The chain box is not in contact with the screen to make the screen life extend.

Technical Data of Drag Chain Extractors

|

Model |

Capacity |

Power(kW) |

Application |

Notes |

|

YJCT100 |

80-120t/d |

2.2 |

Oil extraction of various of oilseeds |

It’s extremely suitable for fine oil materials and oil materials with high oil content, little residual oil.

|

|

YJCT120 |

100-150t/d |

2.2 |

||

|

YJCT150 |

120-160t/d |

3 |

||

|

YJCT180 |

160-200t/d |

4 |

||

|

YJCT200 |

180-220t/d |

4 |

||

|

YJCT250 |

200-280t/d |

7.5 |

||

|

YJCT300 |

250-350t/d |

11 |

||

|

YJCT350 |

300-480t/d |

15 |

||

|

YJCT400 |

350-450t/d |

22 |

||

|

YJCT500 |

450-600t/d |

30 |

Technical Indicators of Drag Chain Eactraction (e.g., 500T/D)

1. Steam consumption is less than 280kg/t (soybean)

2. Power consumption: 320KW

3. Solvent consumption is less than or equal to 4kg/t (6 # solvent)

4. Pulp oil residue 1.0% or less

5. Pulp moisture 12-13% (adjustable)

6. Pulp containing 500 PPM or less

7. The enzyme activity of urease was 0.05-0.25 (soybean meal).

8. Leaching crude oil total volatiles are less than 0.30%

9. The residual solvent of crude oil is 300 PPM or less

10. Mechanical impurity of crude oil is less than 0.20%

Product detail pictures:

Related Product Guide:

Our organization insists all along the quality policy of "product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as the consistent purpose of "reputation 1st, purchaser first" for Manufacturing Companies for Olive Oil Extractor - Edible Oil Extraction Plant: Drag Chain Extractor – Fotma , The product will supply to all over the world, such as: Turkey, Thailand, New Orleans, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.