One of Hottest for Cooking Oil Filling Machine - 6YL Series Small Screw Oil Press Machine – Fotma

One of Hottest for Cooking Oil Filling Machine - 6YL Series Small Screw Oil Press Machine – Fotma Detail:

Product Description

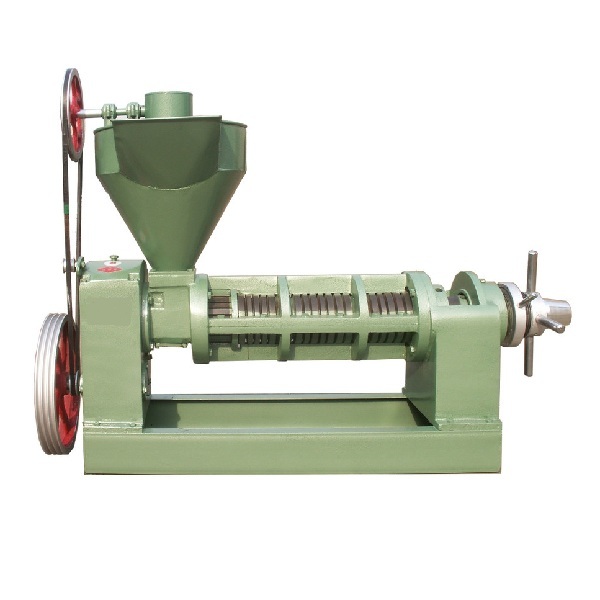

6YL Series small scale screw oil press machine can press all kinds of oil materials such as peanut, soybean, rapeseed, cottonseed, sesame, olive, sunflower, coconut, etc. It is suitable for medium and small scale oil factory and private user, as well as the pre-pressing of extraction oil factory.

This small scale oil press machine is mainly composed of feeder, gearbox, pressing chamber and oil receiver. Some screw oil press machines areequipped with electric motors as required. Pressing chamber is the key partwhich contains a pressing cage and a screw shaft rotating in the cage. An electric cabinet is also necessary to control the whole working procedure.

The operating principle of small scale screw oil press machine

1. When screw oil press machine is on work, material enters the extruding chamber from the hopper and then moves forwards by the rotating pressing screw and is pressed.

2. Under high temperature condition in the chamber, there is quite strong friction among press screw, chamber and the oil materials.

3. On the other hand, root diameter of the pressing screw carries larger from one end to the other.

4. Hence when rotating, the thread not only pushes particles moving forwards but also turns them outwards as well.

5. Meanwhile, particles adjacent the screw will rotate along with screw’s rotating, causing every particle inside the chamber to possess different speed.

6. Therefore, relative movement among particles creates neat which is necessary during manufacturing because of helping protein change property, damage colloid, increase plasticity, decrease oil’s elasticity, resulting in high oil.

The small scale screw oil press machine has its own features and markets

1. Made of high quality steel, wear-resistant and easy to clean.

2. With the properly designed pressing chamber, the increased pressure in the chamber highly improves working efficiency.

3. Low residual: the oil residual in cake is only about 5%.

4. Little land occupancy: only 10-20m2 is enough.

Technical data

|

Model |

6YL-80 |

6YL-100 |

6YL-120 |

6YL-150 |

|

Diameter of shaft |

φ 80mm |

φ 100mm |

φ 120mm |

φ 150mm |

|

Speed of shaft |

63r/min |

43r/min |

36r/min |

33r/min |

|

Main motor power |

5.5kw |

7.5kw |

11kw |

15kw |

|

Vacumm pump |

0.55kw |

0.75kw |

0.75kw |

1.1kw |

|

Heater |

3kw |

3.5kw |

4kw |

4kw |

|

Capacity |

80-150Kg/h |

150-250Kg/h |

250-350Kg/h |

300-450Kg/h |

|

Weight |

830Kg |

1100Kg |

1500Kg |

1950Kg |

|

Dimension(LxWxH) |

1650x1440x1700mm |

1960x1630x1900mm |

2100x1680x1900mm |

2380x1850x2000mm |

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for One of Hottest for Cooking Oil Filling Machine - 6YL Series Small Screw Oil Press Machine – Fotma , The product will supply to all over the world, such as: Peru, Macedonia, Kuwait, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.