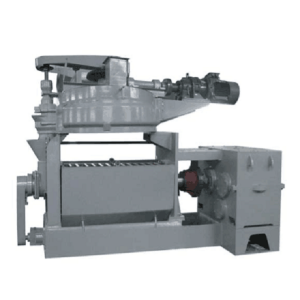

LD Series Centrifugal Type Continous Oil Filter

Features

1. Operation: vertical centrifugal oil refining, rapid separation of oil sludge, the whole process only takes 5-8 minutes.

2. Automatic control: set the timer, automatically stop the oil, the oil is not stored in the machine, and the refining of hundreds of kilograms only needs to be cleaned once.

3. Installation: flat floor, can be installed without screw fixation.

Technical Data

|

Model |

LD1 |

LD2 |

L380 |

|

Capacity |

250kg/h |

400kg/h |

300kg/h |

|

Drum Size |

Φ419*220mm |

Φ546*220mm |

Φ166*550mm |

|

Spindle speed |

1440 rpm |

1440 rpm |

4100 rpm |

|

Main Motor Power |

2.2kw |

3kw |

3kw |

|

Voltage |

380V/50Hz |

380V/50Hz |

380V/50Hz |

|

Connection |

Direct connection |

Belt type |

|

|

Weight |

120kg |

155kg |

|

|

Dimension |

600*600*820mm |

950*700*930mm |

1020*1050*1000mm |

|

Slag-out |

Manual |

Manual |

Automatic |

Write your message here and send it to us